For any company examining which heavy material handling equipment to invest in there are many factors which influence the buying decision: economics, factory productivity, environmental issues, maintenance issues, operator skills and training, space utilisation, energy consumption, distance and more. However, where people and property are concerned SAFETY should be at the top of the list.

There are various categories of handling equipment available for moving extremely heavy loads.

Heavy Duty Platform Carts – wheel based

Heavy Duty Platform Carts – on rails

Bridge Cranes, Gantry Cranes, Jib Cranes

Hoists

Special Heavyweight Forklifts (generally suitable for weights up to 15 to 20 tons)

The hazards involved in moving extremely heavy load are potentially many and quite serious. They involve:

- crushing due to falling loads

- equipment failure with resulting consequences

- surface hazards due to poor flooring or obstacles

- operator risks due to poor training or operator distractions

- staff risks and injuries due to unsafe operating procedures or unsafe equipment

- property risks due to unsafe operations or collisions

- environmental hazards such as slippery floors, obstacles en-route, hanging wires, wind and more

- unsafe loads due to improper loading and preparation

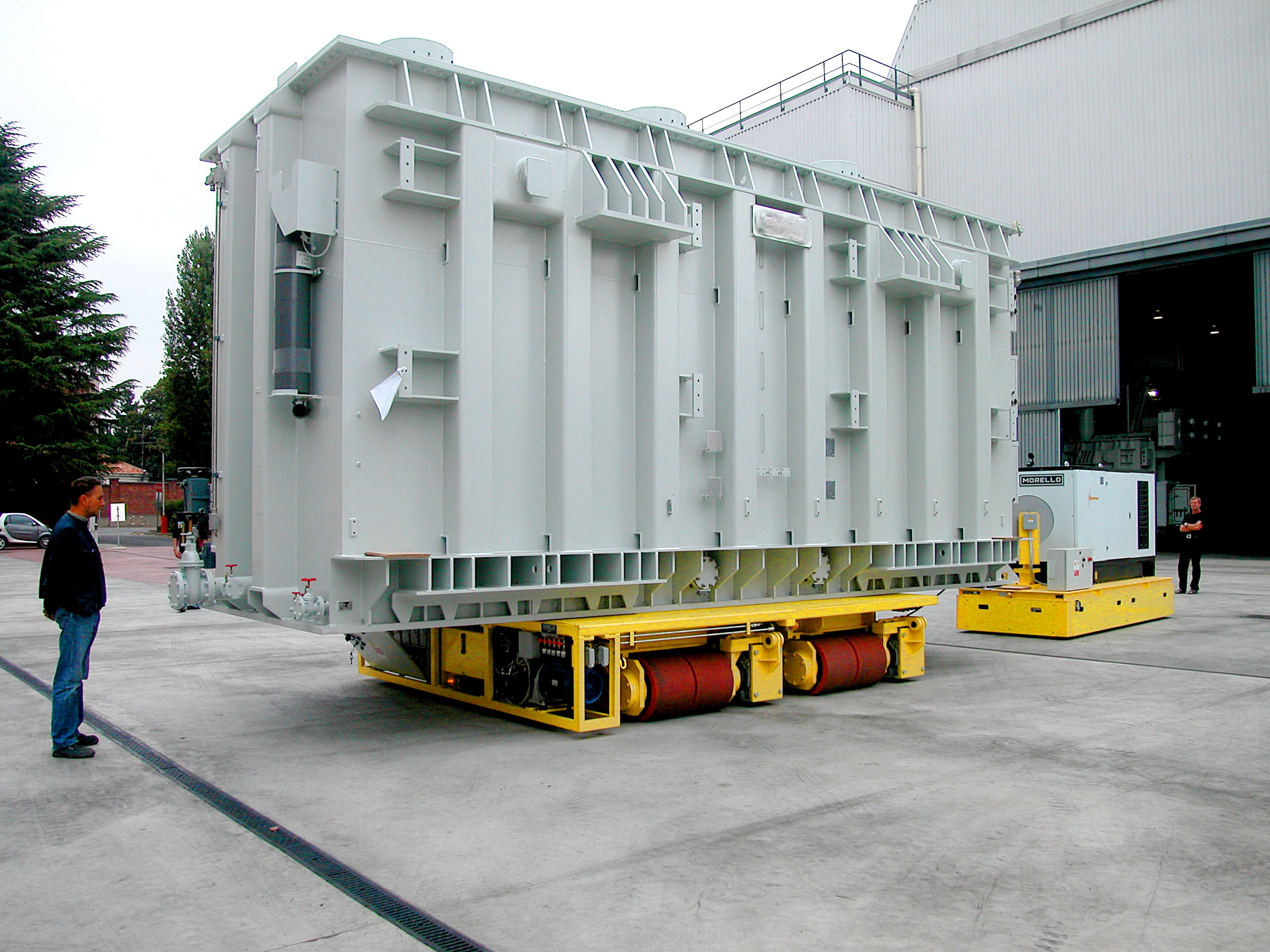

Morello is a leading manufacturer of heavy-duty platform carts (industrial trucks or vehicles) and is highly specialised in moving heavy loads of up to 1000 tons in-plant, both indoors and outdoors.

HEAVY DUTY PLATFORM CARTS – LOW RISK SOLUTION

Platform Carts are one of the safest methods for moving extremely heavy loads within the factory for a series of different reasons. Very simply:

- The load is placed in a very stable position on a large steel platform bed

- The platform is supported by and moved on industrial strength wheels

- Movement is smooth and easily managed, braking is stable and gradual

- The driver operates at a distance, using a remote-control command interface

- High tech sensor technology ensures the cart ‘sees’ the obstacles or the people in its path and responds to the situation accordingly. Any number of sensors may be added to the cart depending on the environment and application.

- Minimal operator training is required as a cart can be operated efficiently following approximately an hour of basic training.

- Movement is very precise eliminating the risk of damage to property

- Electric carts are silent

- Air Pollution is zero

- Electric motors have no oil leaks or spillage

- OMNI carts have individual wheel control. Each wheel has its own motor, its own braking, its own hydraulic height adjustment for uneven surfaces and slopes to keep the load always horizontal.

- Operating in tight spaces is part of normal operating procedures for platform carts.

- AGV carts provide an even greater level of safety and precision having all the latest technologies on board to maximise safety and efficiency.

- ATEX version carts can be supplied for operating in volatile, explosive-risk environments.

BRIDGE / GANTRY CRANES – HIGH RISK

Crane operations are potentially very risky and require well trained and experienced operators to avoid causing damage to the load, to property or worse to staff and to the driver/operator himself.

Cranes involve suspending the load at a height, stabilising the load, minimise any swinging movement, and moving the load a distance within the plant above other equipment or people in the area.

The chains or shackles must be strong and bulky enough to hold extreme loads. Managing the chains is a risky business itself, and they can break fingers or worse. The operators must work in direct contact with the chains and with the load. Crane related fatalities occur every year in work environments.

RAILS – LOW RISK

Platform Carts on rails can be a quite efficient solution in some specific types of work environment. The additional risk compared to wheel-based platform carts is the presence of the rails themselves within the environment. These are a tripping hazard and can be an obstacle for moving certain types of smaller wheel-based equipment.

A safety advantage may be the knowledge that the cart and its extreme loads will move along a fixed route and this is easily visible within the plant.

FORKLIFTS – MODERATE RISK

Forklifts are widely used in industry and up to certain weights may be an interesting choice for some manufacturing plants. Apart from the obvious weight limitations, a forklift can be a flexible solution however the safety implications for extreme loads can be quite serious.

There are some well documented safety hazards relating to forklifts which are totally resolved by platform carts.

- 1. Manoeuvring: Rear-end steering gives a tight turn radius for the front of the forklift, but the back end of the truck swings wide during a turn.

- Blind spots: The load being carried can create blind spots for the operator.

- Load stability: Trucks and their loads can become unstable when operating on inclines, on wet, oily surfaces, and on rough terrain.

- Fuelling: Refuelling and recharging operations are particularly hazardous.

- Speed: The forklift’s weight and speed combine as momentum. A forklift operating at a slow speed can do as much damage as a car driving about 15 miles per hour.

Interesting fact: So far, the forklift that has the highest load capacity is the Kalmar forklift in the UK. It is listed in the Guinness Book of Records as having a load capacity of 90,000kg, which is approximately 198416.04 lbs.

CONSIDER THE SAFETY FACTORS

There are many factors to consider when selecting the most suitable heavy material handling technology for your plant. Make sure SAFETY is one of the factors at the top of your list.

If you know the right questions to ask you are more likely to make a better, more informed investment decision!

Contact us. We look forward to speaking with you!

Morello Client Engagement Team: Amedeo Morello, Luca Tibaldi, Stefano Rizzo