Industries around the world are placing greater emphasis on sustainability and reducing their carbon footprint. However, heavy material handling in factories continues to present a significant challenge.

To achieve decarbonization goals, it is essential to replace traditional handling equipment, such as diesel-powered self-propelled cranes, fossil fuel-powered conveyors, and industrial vehicles with internal combustion engines. These machines are major contributors to greenhouse gas (GHG) emissions, driving up operational costs and environmental impact.

Adopting low-carbon alternatives, such as electric flatbed conveyors, is a strategic move to comply with environmental regulations, optimize energy consumption, and promote more sustainable operations.

In this article, we explore the environmental impact and benefits of electric flatbed conveyors, highlighting their role in fostering a more efficient and sustainable industry.

The environmental impact of heavy material handling

Industrial equipment used for heavy load handling is a major contributor to carbon emissions due to its reliance on diesel, gasoline, and other fossil fuels.

Key areas of impact include:

- Fuel combustion emissions: Diesel transporters, cranes, and oversized vehicles emit significant amounts of CO2 and NOx.

- Energy-intensive operations: Moving extremely heavy loads requires high energy consumption, often sourced from non-renewable power grids.

- Supply chain inefficiencies: Poor logistics planning leads to increased fuel consumption and higher emissions during the transportation of heavy loads within factories.

The role of electric flatbed transporters

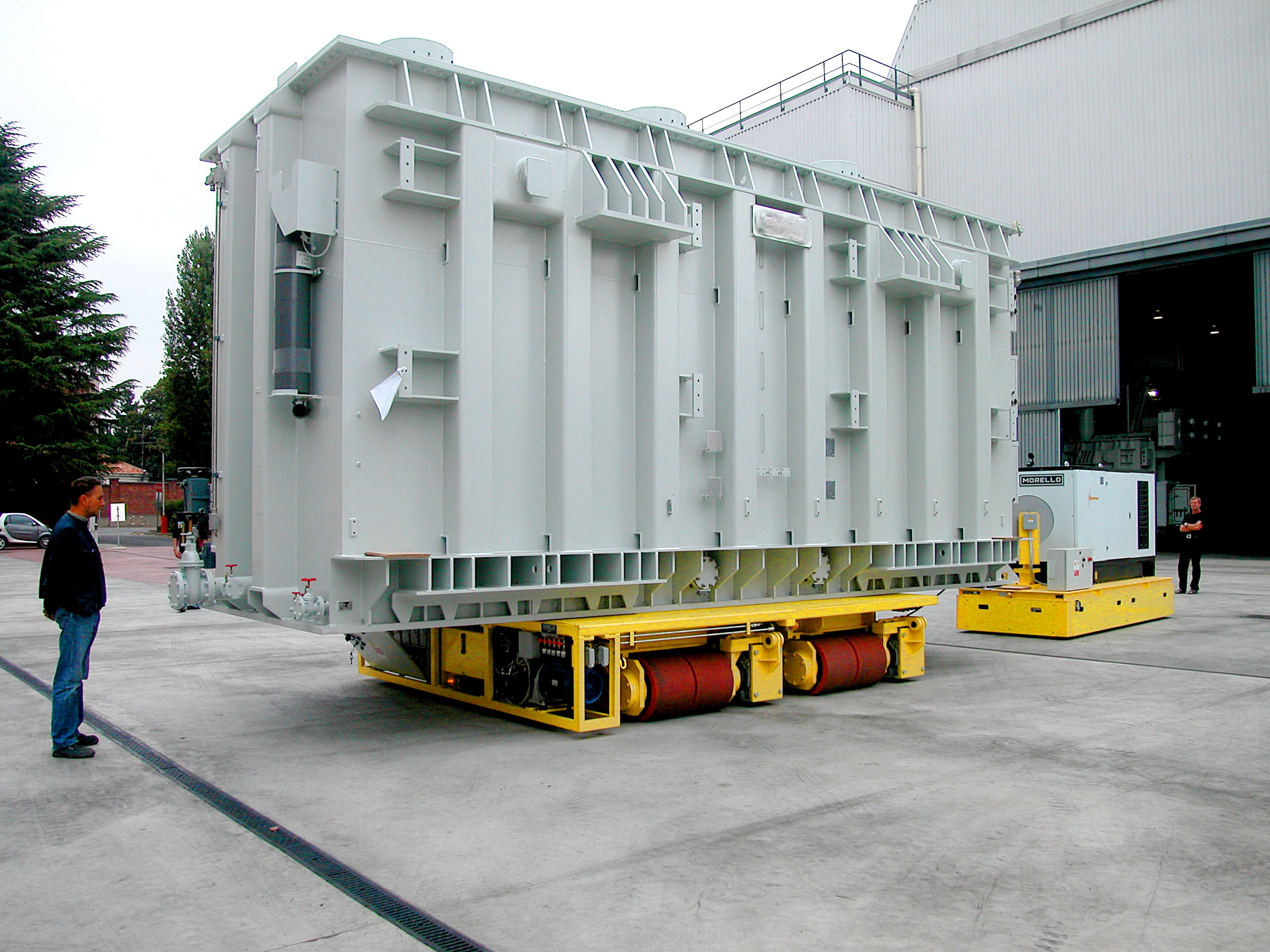

Electric flatbed transporters provide a sustainable solution for handling heavy materials in factories. Powered by batteries, they eliminate direct emissions and offer several operational benefits:

- Zero emissions

Unlike gasoline or diesel-powered vehicles, electric transporters produce no exhaust emissions, significantly reducing the carbon footprint of industrial operations and improving air quality within manufacturing facilities.

- Handling extreme loads

Designed to move loads weighing hundreds of tons, electric flatbed transporters are ideal for industries such as steel manufacturing, shipbuilding, and heavy machinery production. Their high-torque electric motors and robust design ensure efficient transportation of oversized components.

- Energy efficiency and cost reduction

Electric transporters are more energy-efficient than fossil fuel-powered alternatives. They also have lower maintenance and operational costs, leading to substantial long-term financial savings.

- Integration with renewable energy

Factories can further enhance sustainability by charging electric transporters using renewable energy sources, such as solar panels or wind turbines, thus minimizing reliance on carbon-intensive power grids.

- Improved safety and productivity

With smoother acceleration and deceleration, electric transporters reduce the risk of workplace accidents. They can also be equipped with advanced automation and tracking technologies to optimize material handling and movement.

- Noise pollution reduction

Compared to internal combustion engine vehicles, electric transporters operate much more quietly, improving working conditions and reducing environmental noise pollution.

Key considerations for implementing electric transporters

When considering the adoption of electric flatbed transporters, several key factors must be taken into account:

- Battery range and charging infrastructure: Ensuring the availability of adequate charging stations and implementing effective battery management strategies is vital for uninterrupted operations.

- Initial investment costs: While electric transporters may have a higher initial cost compared to traditional alternatives, the long-term savings on fuel and maintenance more than justify the investment.

- Workforce adaptation and training: Although workers may require initial training to familiarize themselves with the new system, operating electric transporters does not necessitate special driving permits.

For Morello’s transporters, our design engineers evaluate each client’s specific operational needs to provide a customized solution that aligns with decarbonization goals, safety standards, productivity requirements, and economic sustainability.

The adoption of electric flatbed transporters is a crucial step in decarbonizing heavy material handling in factories. By reducing emissions, improving energy efficiency, and integrating with renewable energy sources, these transport systems offer a tangible solution for creating a more sustainable industry.

As technology and infrastructure continue to evolve, electric transporters will play an increasingly pivotal role in the future of green manufacturing.

Contact us today to learn more about our electric transport solutions!