AGV

Description

CAPACITY: 0 – 1000 TONS

MORELLO designs and manufactures automated guided carts AGVs tailored to the specific demands of various industrial sectors. Our expertise lies in heavy-load AGVs with capacities ranging from 2 to 1,000 tons.

We produce wheeled automated guided vehicles (AGVs) for material handling automation across diverse industries. These AGVs operate autonomously, requiring no operators or physical guidance, such as rails.

ADVANTAGES OF MORELLO’S HEAVY-LOAD AGVs:

- Reduced operational costs

- Enhanced safety

- Increased accuracy and productivity

- Decreased damage to products and the work environment

- Capability to operate in hazardous or hostile environments (for example explosive environments)

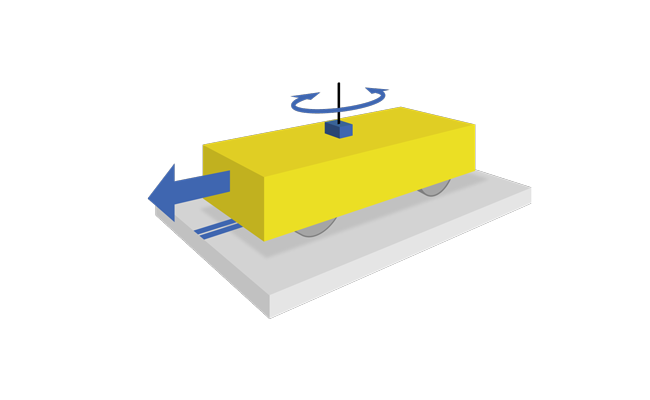

NAVIGATION TECHNOLOGY

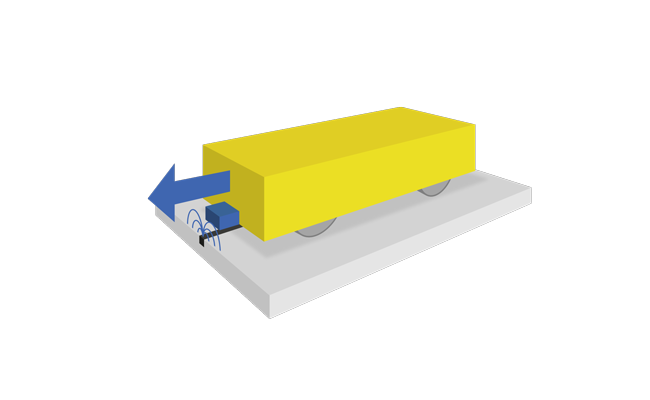

A range of navigation technologies for automated material handling distinguishes MORELLO among AGV manufacturers worldwide. The selection of technology (or a combination of multiple technologies) is made collaboratively with the customer, based on their specific requirements, technical features, and budget. Here are the technologies available for our heavy-load AGV carts.

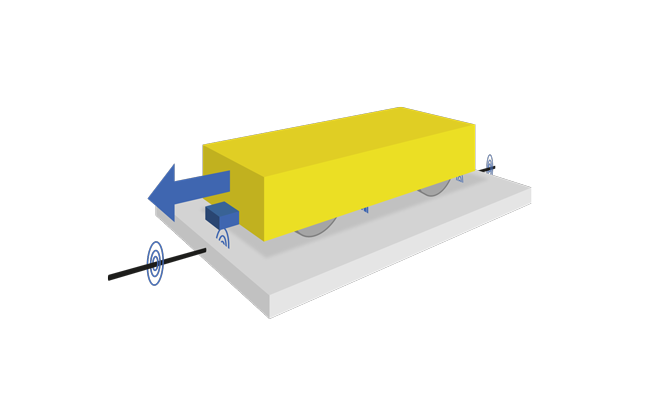

INDUCTIVE GUIDANCE

OPTICAL GUIDANCE

INERTIAL GUIDANCE

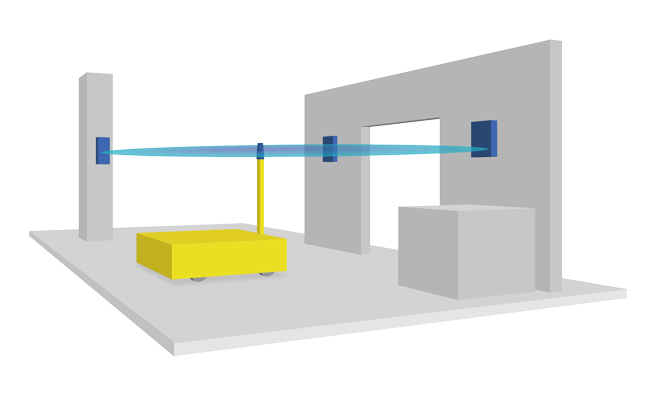

LASER GUIDANCE

MAGNETIC GUIDANCE

dGPS GUIDANCE

SOFTWARE

MORELLO utilizes a combination of proprietary software developed in-house and standard software from leading AGV software houses to ensure maximum flexibility in customizing heavy-load AGV cart geometry, including navigation paths and automation logic integrated into the customer’s production process. We can provide omnidirectional automated guided carts, AGVs equipped with multiple simultaneous navigation technologies, and solutions interfacing with various management systems, including AGV trolleys that connect with automated warehouses and other machinery, as well as AGV ATEX carts.

MORELLO is likely the first company in the world to offer AGVs suitable for hazardous areas. With our extensive knowledge of ATEX environments, we can design and manufacture customized AGVs compliant with ATEX Zone 2 standards. These ATEX automated guided carts significantly enhance safety in environments that pose inherent risks. By utilizing these explosion-proof AGVs, we can reduce the need for operators to work in hazardous settings, thereby minimizing potential accidents.

Technical characteristics

Capacity | from 1 ton to over 1000 tons | |

Dimensions | on request | |

Steering systems | front axle, all axles, ± 90° steering, omnidirectional | See the technology |

Power supply | battery (electric grid or diesel generator on request) | See the technology |

Travel speed | on request (from 1 km/h to 6 km/h) | |

Drive motors | AC motors (hydraulic motors on request) | See the technology |

Steering motors | AC motors (hydraulic motors on request) | See the technology |

Command | touch panel on board, notebook/s, pulpits, customer WMS/ERP | |

Navigation technologies | inductive, magnetic, laser, natural, dGPS, optical, inertial | |

Kind of wheels | solid rubber, polyurethane, pneumatic | |

Lifting deck | on request (lifting stroke from 50 mm) | |

Kind of battery | lead acid, gel, lithium, pure lead | |

Battery life | on request (from 1500 m to over 15000 m) | |

Climbing ability | on request (from 1% to over 20%) | |

Operating environment | indoor, outdoor, offshore | |

Safety devices | laser scanners, sensitive bumpers, ultrasonic sensors | See the technology |

Industry 4.0 ready | yes | See the technology |

Hazardous areas conform (EX) | on request (ATEX – only Zone 2) | See the technology |

AGV Case Studies

How to reduce heavy load handling costs in factories

Decarbonizing heavy material handling in factories with electric flatbed transporters

Automating the movement of heavy materials using industrial AGVs

The advantages of using self-propelled carts instead of tractor-trailer systems for heavy load handling

How to Optimize Heavy Load Handling

AGV Video Gallery

AGV Photo Gallery

For more information